Braking Systems

By 2035 there is expected to be 12 million units of Fully Autonomous Vehicles and 18 million units of Semi-Autonomous Vehicles, this coupled with the majority of New Vehicles featuring Brake Assist results in a number of key drivers for the use of polymeric materials within Braking Systems, this includes:

- Reduce Fuel Consumption (Less Engine Inefficiency)

- Where there is Limited or No Engine Vacuum available (Diesel, Hybrid, Electric)

- Required for ADAS & Autonomous Driving

- Automatic Emergency Braking (Anti Collision)

- Adaptive Cruise Control (ACC)

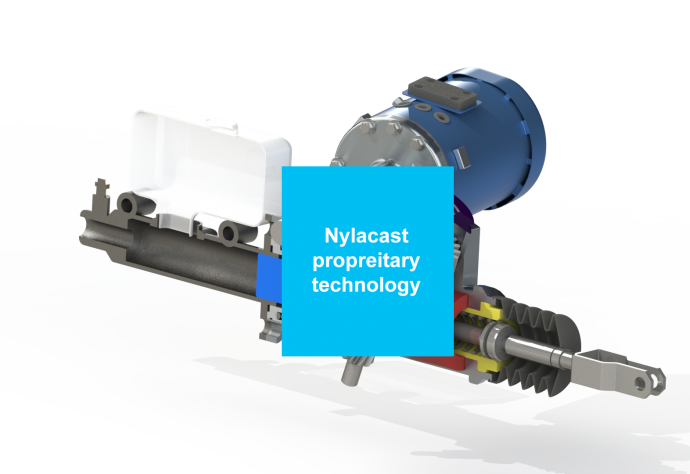

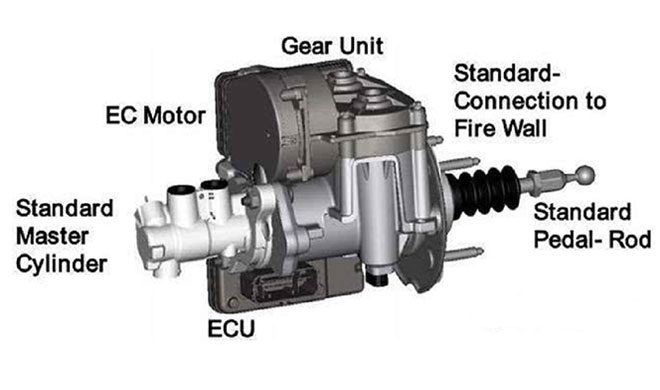

Nylacast Automotive’s significant leadership in the development of safety critical components for the automotive industry is now being applied to Braking Systems. In particular, through a Nylacast Gear Wheel being used in brake booster applications that require variable brake assistance relative to ever changing traffic conditions.

The assistance is transmitted via specially developed wormwheels which either drive a steel pinion onto a Nylacast polymer rack or through a re-circulating ball unit which applies rotational movement to a ball screw, thus transmitting lateral movement.

Both options offer an infinitely variable brake assist force relative to the ever changing road conditions and are applied to ADAS equipped, semi or totally autonomous vehicles.